-40%

ZENA 1/8" NO-Gas Stainless Steel Arc Welding Rods

$ 9.47

- Description

- Size Guide

Description

ZENA®

NO-Gas

tm

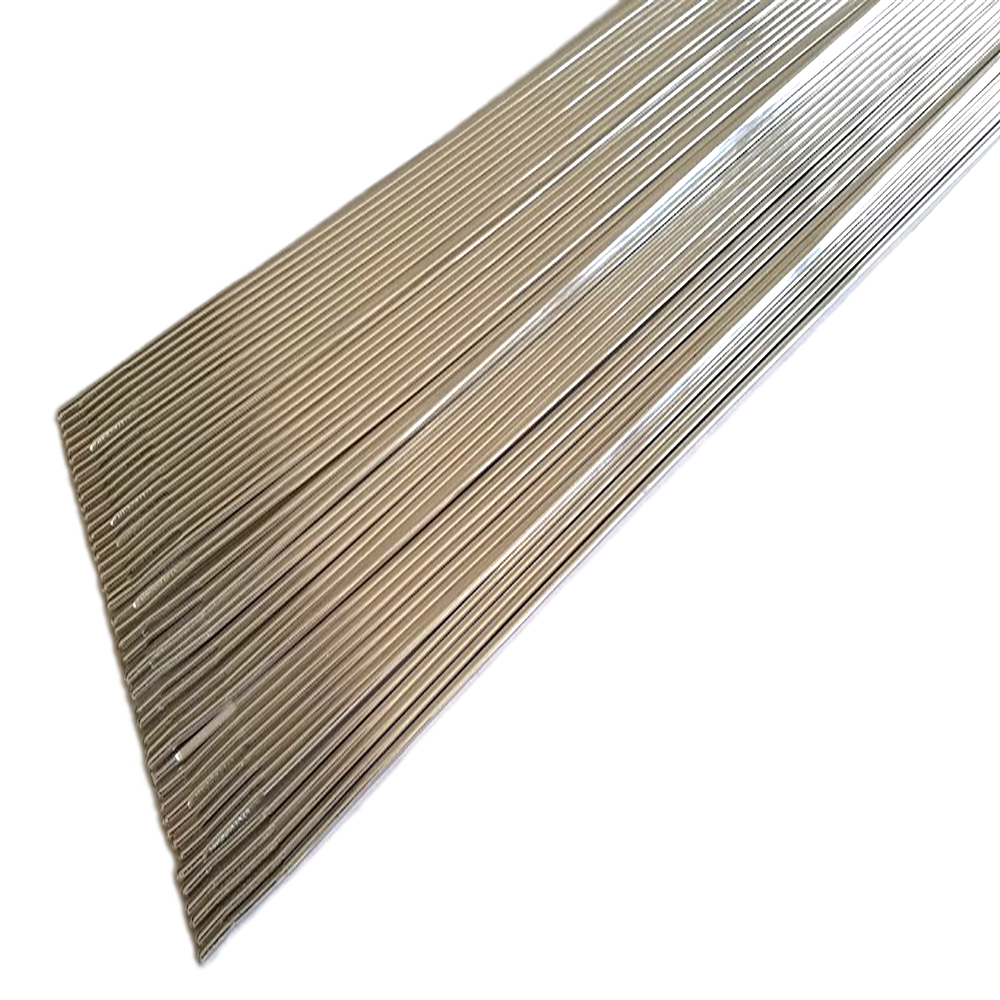

Stainless to Stainless to All Super Strength 1/8" Arc Welding Rods

Use Your Arc Welder to Weld Stainless Steel --

or ANY other type of steel including spring steel!

SquareTrade © AP6.0

Now you can weld stainless steel anywhere that you can arc weld without the need for an oxyacetylene torch, hoses, regulators, or expensive and heavy gas bottles!

These incredibly versatile ZENA® NO-Gas Stainless to Stainless to All Arc Welding Rods let you weld all types of stainless steel creating a super strong 312 Alloy, 128,000 psi weld, highly resistant to cracking or breaking using only your arc welder!

Suitable for welding ALL steels. This rod is the absolute ultimate computer engineered, high alloy electrode for welding every known grade of steel using every know stick electrode power source!

This is the first truly AC-DC mineral-coated high alloy rod that can be used by anyone regardless of prior welding experience. The key is an arc so ionized that you cannot short it out!

Because of the exceptional strength and crack resistance of welds made with these rods, they are ideal for repairing tools, dies, spring steel, and for joining all types of dissimilar metal combinations -- except for Aluminum and Copper alloys. These rods are also recommended for repairing worn parts and an an underlay for hard-facing.

You can also use these special stainless steel welding rods for:

joining stainless steel to other types of steel (including spring steel), OR

joining all types of dissimilar steels (including spring steel), OR

welding spring steel, OR

for increasing corrosion resistance,

OR

to produce exceptionally strong, low distortion welds at low welding temperatures

.

Description:

Highly versatile stainless steel arc welding rods with an engineered deposit chemistry that has the perfect ratio of metallics to offer superior crack resistance and to provide superior performance when joining dissimilar steels.

High chromium, nickel alloy for use with AC or DC reverse polarity in all positions. Designed to produce weld deposits of exceptional strength -- tensile strength 128,000 PSI (almost twice that of average rod). Excellent resistance to corrosion, most chemicals, fertilizers, sulfur, and salts. This alloy maintains its strength and corrosion resistance at high and low temperatures. A balanced metallurgical structure produces high crack resistance under the toughest welding conditions and service applications. This material has good wear resistance, overlays take a high polish and it is one of the best materials for welding dissimilar metals -- including spring steel. It welds as very low amperages, reducing distortion, base metal dilution and its low heat input keeps thermal stresses in welded joints at a minimum.

A special flux formulation eliminates slag interference in horizontal fillets and which produces slag designed to turn to powder -- a feature which makes these electrodes also ideal for stud pull applications.

Mechanical Properties:

Tensile Strength

(psi & N/mm

2

)

Yield Strength

(psi & N/mm

2

)

Elongation

Reduction of area

Hardness

128,000 psi

(880 N/mm

2

)

186,000 psi (1280

N/mm

2

) work hardened

90,000 psi (630 N/mm

2

)

32%

25%

Brinell 225

Recommended Welding Current Type / Polarity:

DC reverse polarity (electrode positive) or AC

Rod Diameters:

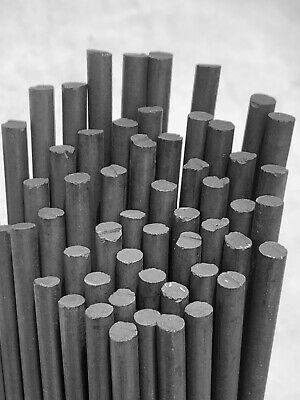

1/8" (14 rods/lb)

Recommended Amperage:

Rod Diameter

1/8" (3.25 mm)

Minimum Amperage

60

Maximum Amperage

110

Product Features:

Excellent wear resistance.

Excellent crack resistance.

Exceptional strength.

Recommended Welding Techniques:

Clean weld area to be free of rust, grease, paint, or other materials which can cause weld contamination. It IS NOT necessary to grind flame cut edges.

Adjust amperage to recommended range for electrode size. .

Tilt electrode 15 degrees in the direction of travel.

Maintain a short arc length and use stringer beads.

For rapid filleting, raise amperage slightly and drag weld inclining the electrode 45 degrees in the direction of travel.

Back whip craters and remove slag between passes.

A 90 degree V-joint should be used when joining heavy sections.

Upon cooling, slag can easily be removed by light chipping and brushing.

Use Flat, Horizontal, Vertical Up, and Overhead Positions.

Typical Applications:

Horizontal fillet welds in all grades of construction steels

Welding every know grade of tool steel including pre-hardened types

Joining abrasion resistant steels, Hadfield and other austenitic manganese steels

Joining heat and corrosion resisting steels

Mending specialized iron-base castings with high carbon contents

Repairing and fabricating tools and dies of all types

Packaging:

1 lb. box (14 rods)

Larger packs/quantities available as special order items.

ZENA

and NO-Gas are trademarks owned by ZENA, Inc. for its welding systems and related products.

©

Copyright 2004 by ZENA, Incorporated. All rights reserved.

NOTE: These rods will work with engine driven welders made by Miller, Lincoln, Hobart, Century, Esab, HTP, Mitsubishi, Thermal Arc, and other companies. When comparing rod specifications, you will find that they function well with ZENA 150A and 200A welders which are comparable to, and will do the same job as, for example, a Miller 225 Bobcat welder, a Hobart 250A welder, a Century 200A welder, or a Lincoln Ranger 8 welder. Of course, 160A, 175A, 180A, 275A, or even 300A, or 400A welders would be also in the same category. MIG and TIG torches made by companies like Tweco and Forney are also compatible with this technology.

NOTE2: In addition to service trucks (particularly popular are Ford Chevrolet and Dodge Diesels) and all types of 4x4's (including Jeep, International, and Toyota), these rods can also be used with all types of heavy equipment, including backhoes, front end loaders, track loaders, forklifts, and tractors as well as all types of utility vehicle.