-40%

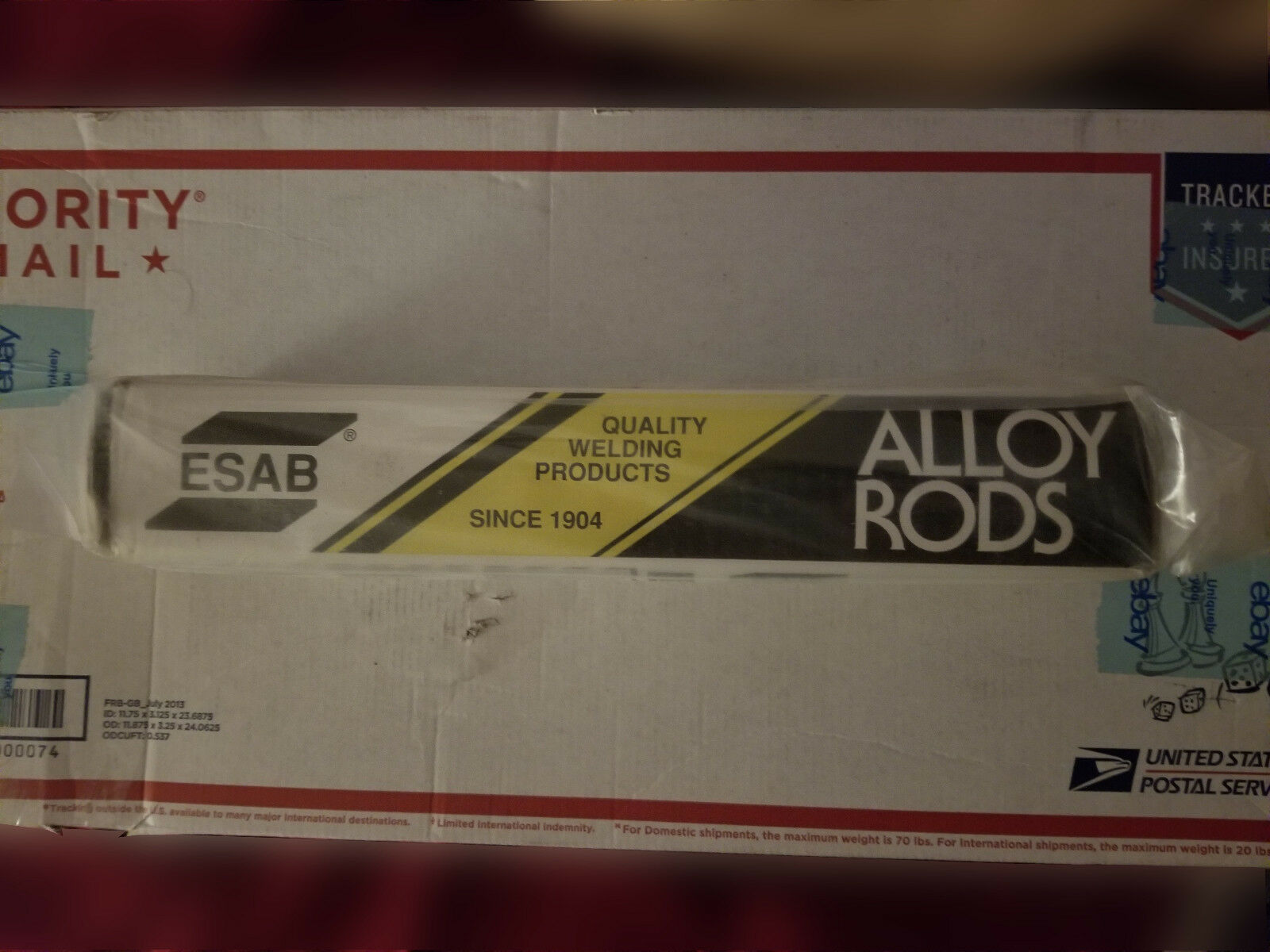

E6013 ESAB Sureweld 1/8" x 14" 11 lbs electrode stick welding rod, Made In USA!

$ 18.45

- Description

- Size Guide

Description

MADE IN U.S.A. !!!!Sureweld SW-15 is ESAB's previous name for what they now call Sureweld 6013.

Instead of paying premium-price for other name-brand electrodes made in Mexico or China, or taking a chance with cheap imported electrodes of unknown quality and specification with a resellers brand name slapped on them, these are American-made super-high quality electrodes made by ESAB! These electrodes are smooth running and consistent, with a flux that creates an easy to remove slag.

Each box of electrodes are still sealed in the factory plastic over-wrap. I opened one for my own use and to take pictures, but be assured the box(es) of electrodes you receive will still be sealed in the original plastic over-wrap. Please note that one or both ends of the cardboard box inside the plastic may be torn open at the seam, however the thick plastic overwrap remains sealed.

SUREWELD SW-15 (AWS E6013)

Sureweld SW-15 has a wide range of applications for light gauge and heavy plate. High heat and speeds can be used without undercut. Slag is easy to clean and on heavy plates is often self-cleaning.

Typical applications include metal fixtures, road equipment, farm machinery, building structures, storage tanks, iron work, vehicle bodies, thin sheet metal.

Industries

Industrial and General Fabrication

Mobile Equipment

Ship/Barge Building

Welding Process

Welding-SMAW/MMA (Stick)

Procedure

For flat welds, tilt 5 to 10° in direction of travel holding a medium arc. On horizontal fillets, tilt 5 to 15° in direction of travel at an angle bisecting vertical and base plate, maintaining a short arc length. Vertical-up, use a weaving “U” or “V” arc motion using medium to short arc length. With overhead use a circular motion.

Typical Tensile Properties

Condition___

Tensile Strength___

Yield Strength___

Elongation___

Reduction in Area

As Welded

71 ksi

63 ksi

24 %

49 %

Typical Weld Metal Analysis %

C______

Mn_____

Si_____

S_______

P_____

0.06%

0.32%

0.23%

0.013%

0.012%

Deposition Data

Diameter___

Current______

Deposition Rate___

Efficiency (%)___

Optimal Amps

5/64 in.

2.0 mm

40-60 A

1.4lb/h

0.6 kg/h

73.0 %

50A

3/32 in.

2.4 mm

60-90A

1.6 lb/h

0.7 kg/h

73.0 %

85A

1/8 in.

3.2 mm

120-135 A

2.1 lb/h

1.0 kg/h

73.0 %

125 A

5/32 in.

4.0 mm

140-190 A

2.6 lb/h

1.2 kg/h

75.6 %

140 A

5/32 in.

4.0 mm

140-190 A

3.0 lb/h

1.4 kg/h

74.1 %

160 A

5/32 in.

4.0 mm

140-190 A

3.5 lb/h

1.6 kg/h

71.2 %

180 A

3/16 in.

4.8 mm

170-230 A

3.2 lb/h

1.5 kg/h

73.9 %

180 A

3/16 in.

4.8 mm

170-230 A

3.8 lb/h

1.7 kg/h

71.1 %

200 A

3/16 in.

4.8 mm

170-230 A

4.1 lb/h

1.9 kg/h

72.9 %

220 A

7/32 in.

5.6 mm

250-300 A

5.3 lb/h

2.4 kg/h

71.3 %

250 A

7/32 in.

5.6 mm

250-300 A

5.7 lb/h

2.6 kg/h

73.0 %

270 A

7/32 in.

5.6 mm

250-300 A

6.1 lb/h

2.8 kg/h

72.7 %

290 A

1/4 in.

6.4 mm

290-340 A

6.2 lb/h

2.8 kg/h

75.0 %

290 A

1/4 in.

6.4 mm

290-340 A

6.5 lb/h

2.9 kg/h

73.5 %

310 A

1/4 in.

6.4 mm

290-340 A

7.1 lb/h

3.2 kg/h

72.1 %

330 A

Approvals:

ABS, AWS A5.1, CWB, CSA, W48.1, E41013

Classifications:

AWS A5.1, ASME SFA 5.1 (A-1, F-2), E6013

Alloy Type:

Carbon Manganese

Coating Type:

Rutile-acid potassium

Electrode Imprint Marking:

6013

Welding Current:

AC, DC+, DC-

Position:

All